|

1.Introduction

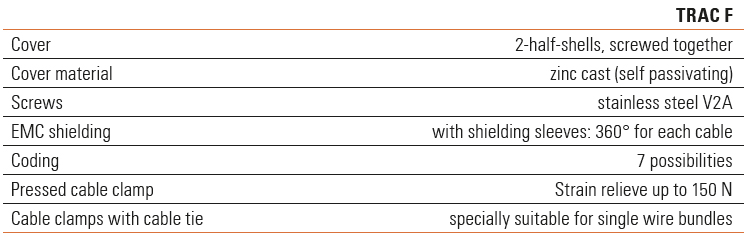

GIMOTA AG developed the plug-case TRAC F, to carry standard contact-insert of the types F, DM and H according to EN IEC 60603-2

(DIN 41612). Particularly the assembled plug is conceived for connecting electronic control devices. Each cable (up to 6 entries )can be applied

with 360° EMI-shielding.

The two-piece TRAC F case in zinc-cast allows to connect up to six cables, with an outer diameters of up to 14mm. The case can also be coded

if necessary, to avoid connecting failures.

For cable diameters up to <12 mm the same cable-clamps are used as with the data connectors D-SUB TRAC. The same compression tools are

therefore applicable.

Ensure correct mounting of the TRAC F plug use: suitable fixation frame is FSMF-41612.

Assembled connectors correspond to the following requirements:

• EN 60529 Protection class IP44/for indoor application only

• IEC 61373, VDE 0115-106 shock and vibrationtest)

TRAC F plugs may be supplied as single components or connectors sets.

To order connector-sets, the following information is necessary:

• number of required cable entrances

• outer diameters of cables and type of cable with/without EMC-shielding for each admittance

• standard number of contacts (48/31/15) - others layouts available on request

and, if required:

• type and number of contacts (single contacts or strip-contacts)

• supply of coding components

• supply of fixation frames

2.Technical information

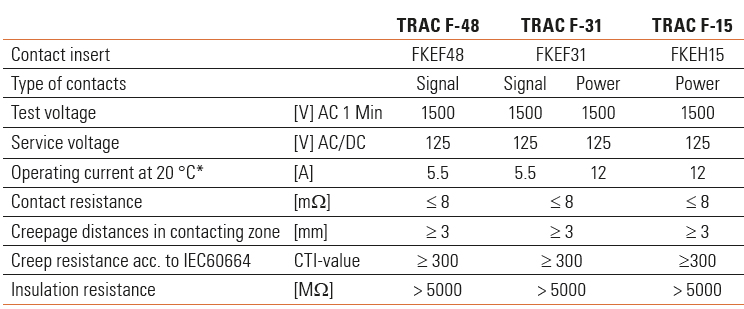

Electrical properties

All electric data are valid at sea level and an environment temperature of 20 °C. Deviating environment conditions are to be taken into account at the connector evaluation.

*) Valid for signal contact, consider the rating curves according to EN IEC 60603-2 for connectors

Thermal properties / Fire characteristic Mechanical properties - connector

Mechanical properties - connector Mechanical properties - contacts

Mechanical properties - contacts

Signal contacts are available as single contacts or for automated processing, as contact-strips.

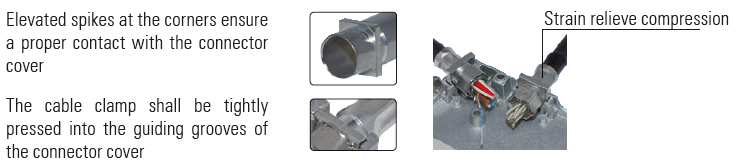

Cable strain relieve

The cable is fixed to the cable clamp by a strain relieve compression. Cable clamps are available in diameter from 6 up to 12 mm. This allows

to connect cables of any diameters, 6 up to 12 mm. If necessary, we recommend the use of heat shrinking tube to adjust the cable diameter to

the cable clamp. In this case a verification of the strain relieve with a test force of at least 150 N during 1 Minute shall be considered.

Our pressing tools ensure an invariant pressing process result if properly operated to achieve clear surface contact of the two die shells.

EMI-shielding

To guarantee a 360° EMC protection, the TRAC F connector conclude a separate compressable shieldingsleeves that tightly connects the

cable shield to the cable clamp. The cable clamp shoulder is additionally equipped with small spikes to provide an adequate and secure contact

between case and cable clamp.

The shielding sleeve are easily positioned and pressed with the appropriate GIMOTA compression tool.

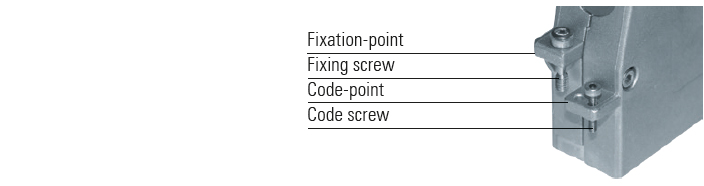

Coding

To code the TRAC F connector code screw at the connectorhood and code pins at the fixation frame are required. The coding of

TRAC F connectors is preferably to be set during the final assembling, to avoid false coding configurations.

Coding is very easy:

1. Screw the code-screws in the code-point at the plug as per coding plan.

2. Fill the unused code-holes at the fixation-frame with the corresponding code-pins

|